Pre Preparation of Food

To be successful in the #FoodService industry, cooks need more that the ability to prepare delicious, attractive, and nutritious foods. They must have a talent for organization and efficiency. In any #kitchen thee are a great many tasks to be completed over a given time and by a limited number of workers. No matter when these tasks are done, they all must come together at one crucial point: service time. Only if pre preparation has been thoroughly and systematically will service go smoothly.

Good chefs take pride in the thoroughness and quality of their pre-preparation or mise-en-place (pronounced meez-on-plahss). This French term meaning “everything put in place,” has become almost a professional password in kitchens, because food service professionals understand its importance to the success of the establishment.

This lesson deals with the basic concepts of pre preparation as well as a number of specific operations that are normally part of the mise-en-place.

MISE EN PLACE:

“EVERYTHING READY”

Even on the simplest level, prep reparation is necessary. If you prepare only one short recipe, you must first.

- Assemble your tools.

- Assemble your ingredients.

- Wash, trim, cut, prepare, and measure your raw materials.

- Prepare your equipment (preheat oven, line baking sheets etc)

Only then can you begin the actual preparation. When meat items are to be prepared in a commercial kitchen, the situation is much more complex. Dealing with this complexity is the basis of kitchen organization.

PLANNING AND ORGANIZING FOR PRE-PREPARATION

The problem

Every food service operation faces a basic conflict between two unavoidable facts:

- There is far too much work to do in a kitchen to leave until the last minute, so some work much be done ahead.

- Most food is at their best quality immediately after preparation, and they deteriorate as they are held.

The solution

To solve this problem the chef must plan the prep-reparation carefully. Planning generally follows these steps:

Break down menu items into its stages of production. Turn to any recipe, note that the procedures are divided into a sequence of steps, which must be done in a certain order to make a finished product.

Determine which stages may be done in advance.

- The first step of any recipe, weather written or not, is always part of advance preparation: assembling and preparing the ingredients. This includes cleaning and cutting procedure, cutting and trimming meats, and preparing breading and batters for frying.

- Succeeding steps of a recipe maybe done in advance if they can then be held without loss of quality.

- Final cooking should be done as close as possible to service, for maximum freshness.

Frequently separate parts of a recipe, such as a sauce or stuffing, are prepared in advance, and the dish is assembled at the last minute.

In general, items cooked by dry heat methods, such as broiled steaks, sautéed fish, and French-fried potatoes, do not hold well. Large roasts are an important exception to this rule. Items cooked by moist heat, such as braised beef, soups, and stews are usually better suited to re heating or holding in a steam table. Very delicate items should always be freshly cooked.

Determine the best way to hold the item at its final stage of pre preparation.

- Sauces and soups are frequently kept hot, above 1400f(600c), for service in steam tables or other holding equipment. Many foods such as vegetables, however, should be kept hot for only short periods, because they quickly become over cooked.

- Refrigerator temperatures below 400F (40C) are best for pre serving the quality of most foods, especially perishable meats, fish, and vegetables, before final cooking or reheating.

Determine how long it takes to prepare each stage of each recipe. Plan a production schedule beginning with the preparation that takes the longest. Many operations can be carried on at once, because they don’t all require your complete attention the full time. It may take six to eight hours to make a stock but you don’t have to stand and watch it all that time.

Examine recipes to see if they might be revised for better efficiency and quality as served.

For example:

- Instead of preparing a full batch of green peas and holding for service in the steam table, you might blanch and chill them and heat portion to order in a sauté pan, steamer, or microwave oven.

- Instead of holding a large batch of veal scaloppine in mushroom sauce in the steam table, you might prepare and hold the sauce, sauté the veal to order, combine the portion of sauce, and serve fresh from the pan.

Caution: – unless you in charge of the kitchen do not change a recipe without authorization without your supervisor.

The Goal

The goal of pre preparation is to do as much work in advance as possible without loss of quality. At service time, all energy can then be used for finishing each item immediately before serving, with the uttermost attention to quality and freshness. Many preparations techniques in common use are designed for the convenience of the cooks at the expense of quality. Remember quality should always take highest priority.

PREPARATION FOR SET MEAL SERVICE AND EXTENDED MEAL SERVICE

Set meal service

- All the customers eat at one time.

- Often called “quantity cooking” because large batches are prepared in advance.

- Examples: school, cafeterias, banquets, employee dinning rooms.

The traditional methods of set meal preparation, still widely used have been to prepare the entire quantity of each item in a single large batch and too keep it hot for the duration of the meal service. This method has two major disadvantages.

- Deterioration of quality due to long holding.

- Large quantities of left over.

Modern high-speed equipment such as pressure steamers, convection ovens, infrared ovens, and microwave ovens, make possible a system small batch cooking. Quantities needed are divided into small batches, placed in pans ready for final cooking or heating, and then cooked only as needed. Its advantages sure as follows: –

- Fresher food, because it is not held so long.

- Fewer leftovers because pans not needed are not cooked.

- Small batch cooking also accommodated items prepared in advance and frozen or chilled for storage.

Extended meal service.

- Customers eat at different times.

- Often called “a la carte cooking” because customers usually select items from a written menu (“carte” in French)

- Examples: restaurants, short –order counters.

Individual items are cooked “to order” rather than cooked ahead, but prep reparation is extensive, down to the final cooking stage.

The short order cook, for example must have everything ready to go: cold meats, tomatoes and other sandwich ingredients sliced and arranged, spreads prepared and ready, hamburger patties shaped, garnished prepared and so on. If the cook has to stop during the service to do any of these things, orders will back up and service will get behind.

A steak that takes10 minute to broil may be cut and trimmed in advance, but broiling should be started 10mins before it is to be served.

Obviously if the last step in the recipe is to braise the item for 1 ½ hrs one cannot wait until an order comes in before beginning to braise. An experienced cook will estimate very closely how many orders will be needed during the meal period and prepare a batch that ideally will be finished when service begins.

Preparation techniques are adapted to style of service

Note the difference in these two methods for Chicken Chasseur in both cases; the final product is chicken in a broom sauce with mushrooms, shallots, white wine and tomatoes.

- Quantity method: – Chicken Chasseur.

- Brown chicken in fat; remove.

- Sauté shallots and mushrooms in same fat

- Add flour to make a roux.

- Add white wine, tomatoes brown stock and seasoning; simmer until thickened.

- Add chicken; braise until done.

- A la carte method: – Chicken Chasseur

- Prepare sauce Chasseur in advance; hold in brain Marie.

- For each order :

- Brown chicken in sauté pan and finish cooking in oven.

- Deglaze pan with white wine; reduce.

- Add 1 portion of sauce; add chicken and simmer briefly; serve.

CLEANING AND CUTTING THE RAW MATERIALS

ROUGH PREP

Rough prep means the preliminary processing of ingredients to the point at which they can be used in cooking. Rough prep usually applies to fresh vegetables and fruits, as they usually require much washing and trimming. Meat and other ingredients may also require cutting and trimming. (Some operation do much of their own meat cutting, others buy ready cut portion control meats). Vegetable, meat, poultry, and seafood chapters contain detailed information on preliminary preparation of specific items.

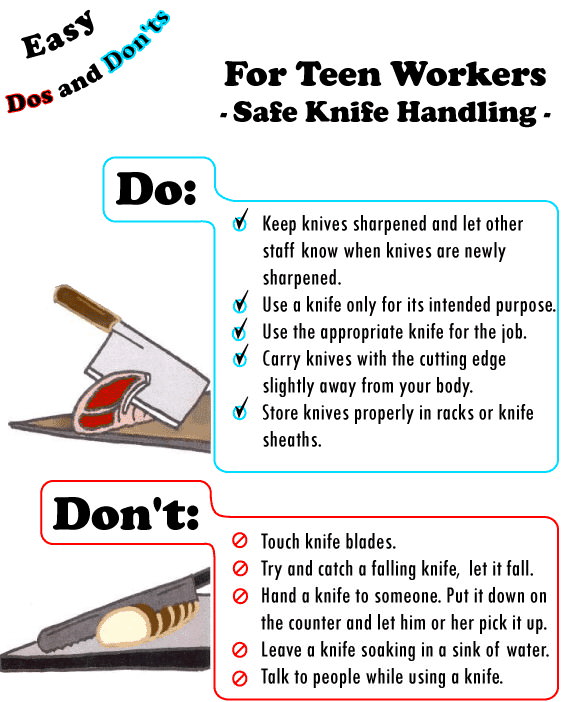

USING THE KNIFE

There are many kinds of labor-saving equipment for cutting, chopping, and slicing fresh foods. The chef’s knife or French knife however, is still the cooks most important and versatile cutting tool. The knife is more precise than a machine. Unless you are cutting a large quantity the knife can even be faster. Cleaning a large machine takes time. To get the best use, out of your knife, you must learn to keep it sharp and handle it properly.

Keeping a sharp knife.

The sharpening stone.

A stone is the best tool for sharpening a chef’s knife. Electric sharpeners wear away too much of your expensive knife, and they do not make as good an edge.

The steel.

This tool is used not to sharpen the edge but to true the edge (to perfect it or to smooth out irregularities) and to maintain the edge (to keep it sharp as it is used).

Handling the knife

The grip

Proper grip gives you maximum control over the knife. The proper grip increases your cutting accuracy and speed, it prevents slipping, and it lessens the chance of an accident. The type of grip you use depends in part on the job you are doing and the size of the knife. Many chiefs feel that actually grasping the blade with the thumb and forefinger in this manner gives them greatest control.

BASIC CUTS AND SHAPES

Cutting food products into uniform shapes and sizes is important for two reasons:

- It ensures even cooking.

- It enhances the appearance of the product

Given below are the names and dimensions of some common shapes.

- Brunoise (broon-wahz);(3mm x 3mm x 3mm)

- Small dice :(6mm x 6mm x 6mm)

- Medium dice: (12mm x 12mm x 12mm)

- Large dice: (2cm x2 cm x 2cm)

- Julienne (or allumette): (3mm x 3mm x 6cm)

- Batonnet: (6mm x 6mm x 6- 7.5cm)

- French fries or pomme frite: 8-12mm sq x 7.5 cm long.

The following terms describe other cutting techniques:

- Chop: to cut into irregular shaped pieces.

- Concasser (con-cass-say): to cut coarsely.

- Mince: to chop into very fine pieces.

- Emincer (em-man-say): to cut into very thin slices (does not mean “to mince”).

- Shred: to cut into thin strips, either with the coarse bade of a grater (manual or power) or with a chief’s knife.

PRELIMINARY COOKING AND FLAVOURING

Advance preparation often requires certain pre cooking and flavoring of ingredients to make them ready for use in the finished recipe. On the most obvious level, if a recipe for a chicken salad calls for cooked, diced chicken you must first cook the chicken before you can proceed with the recipe. A complete cooking procedure, in such a case, is part of the mise-en-place or pre-preparation.

BLANCHING AND PAR COOKING

Partial cooking is a significant part of advance preparation. It requires a degree of culinary skill and judgment to determine when and how much cooking is necessary or desirable. Partial cooking may be done by any moist-heat or dry heat methods. Commonly used are simmering or boiling (par boiling), steaming and deep-frying (especially for potatoes). The term blanching may mean any of these methods, but it usually implies very brief cooking.

There are 4 main reasons for blanching or par cooking: –

- To increase holding quality:

Heating helps preserve the foods by

- Destroying bacteria that cause spoilage.

- Destroys enzymes that dis-colours foods (as when potatoes turn brown) and help them deteriorate.

- To save time:

It takes less time to finish parboiled vegetables for service than it does raw vegetables. Large batches of foods may be blanched and chilled, and individual portions then finished to order.

Items such as roast duck, which would take too long to cook completely to order, are often roasted half to ¾ done, then finished as the order are received.

- To remove undesirable flavors:

Some variety meat and certain strong-flavored vegetables such as rutabaga are sometimes blanched to make them milder and more acceptable to the customers.

- To enable the product to be processed further:

For example, vegetables and fruits such as tomatoes and peaches as well as some nuts are blanched to loosen the skin for peeling.

Sweetbreads are blanched so that they will be firm enough for slicing and breading or other kinds of handling.

MARINATING

To marinate means to soak a food product in a seasoned liquid in order to:

- Flavour the product

- Tenderize the product

Note: The tenderizing effect of the acids in the marinade is relatively small. It is still essential to match the proper cut of meat with the proper cooking techniques for greatest tenderness.

The marinade can also serve as the cooking medium and become part of the sauce. Vegetables marinades, called vinaigrette are served cold with vegetables as salads or hors d’oeuvres without further cooking or processing.

Guidelines for marinating.

- Marinate under refrigeration (unless product is to be cooked in only a few minutes.)

- The thicker the product, the longer it takes for the marinade to penetrate. Some foods are marinated a week or longer.

- Use an acid resistant container, such as stainless steel, glass, crockery, or some plastics.

- Tie spices in a cheesecloth bag (sachet) if easy removal is important.

- Cover product completely with marinades. When marinating small items you may use less liquid, but you must then turn the product frequently for a penetration.

PREPARATION FOR FRYING

Most foods to be deep-fried with a major exception of potatoes are first given a protective coating of breading or batter. This coating serves for a purpose.

- It helps retain moisture and flavor in the product.

- It protects the fat against the moister and salt in the food, which speed deterioration of frying fat.

- It protects the food from absorbing too much fat.

- It gives crispiness, flavour, and good appearance to the product.

BREADING

Breading means coating a product with breadcrumbs or other crumbs or meal before deep-frying, pan-frying, or sautéing.

DREDGING WITH FLOUR

The purpose of dredging is to give a thin even coating of flour to a product. Meats to be sautéed or pan-fried are often dredged with flour to give them an even brown color and to prevent sticking. Vegetables such as sticks of zucchini are sometimes coated only in flour before deep-frying, to give them a slight golden color and very thin coating.

BATTERS

Batters are semi liquid mixtures containing flour or other starch. They are used in deep-frying to give a crisp, flavourful coating. There are many different formulas and variations for batters: –

- Many different liquids are used, including milk, water, or beer.

- Eggs may or may not be used.

- Thicker batters make thicker coatings. Too thick a batter will make a heavy and palatable coating.

- Leavenings are frequently used to give a lighter product. Theses may be

- Baking powder

- Beaten egg white

- Carbonation from the beer or seltzer used in the batter.

HANDLING CONVENIENCE FOODS

Convenience foods are plain and increasingly prominent role in the food service industry. Their use has become so important that no student of professional cooking can afford to be without knowledge of them.

A convenience food may be defined as any product that has been partially or completely prepared or processed by the manufacturer. In other word when you buy a convenience product you are having the manufacturer do some or all of your pre-preparation for you. Of course you must pay for this service as reflected in the price of the product. Although buying the convenience product will likely cost you more than buying the raw material0s, you save in increased kitchen efficiency. As you will remember labor cost as well as food cost must be figured into your menu price.

Processed foods for restaurants and institutions range from partially prepared items that can be used as components in your recipes, such as frozen fish fillets, peeled potatoes, concentrated stock bases, and frozen puff pastry dough, to fully prepared items that need only be reconstituted or served as in, such as frozen prepared entrées and frozen pies and pastries. Some items like frozen French fries have wide acceptance, while other more fully prepared foods continue to be resisted by both customer and operator.

In general, the more completely a product has been prepared by the manufactures the less it will reflect the individuality of the food service operator – the less opportunity the cooks have to give it to their own character and quality.

Is a stock made from “scratch” better than a product made from convenience base? Most quality – conscious chefs would probably answer yes! But the correct answer is “Not if the homemade stock is poorly made”. No matter what product you use, there is no substitute for quality and care. The fresh product is potentially the best, but not if it is badly stored or handled. Convenience foods also need proper handling to maintaining their quality.

Considering the convenience foods as normal products with the part of the pre preparation completed, rather than as totally different kinds of products unlike your normal raw materials, is the key to understanding and handling them probably. Convenience products are not a substitute for culinary knowledge and skill. They should be a tool for the good cook rather than a crutch for the bad cook. It takes as much understanding of basic cooking principals to handle convenience products as it does fresh, raw ingredients, particularly if you want the convenience products to taste as much like the fresh as possible.

Guidelines for Handling Convenience Foods

- Handle with the same care you give fresh and raw ingredients. Most loss of quality in convenience foods comes from assuming that they are damage-proof and can be treated haphazardly.

- Examine as soon as received. Particularly, check frozen foods – with a thermometer – to make sure they have not thawed in transits. Put away at once.

- Store properly. Frozen foods must be held at 00F (-180C) or lower. Check your freezer with a thermometer regularly. Refrigerated foods must stay chilled below 400F (40C) to slow the spoilage. Shelf-stable foods (dry products, canned goods, etc) are “shelf-stable only when stored properly, in a cool, dry place, tightly sealed.

- Know the self-life of each product. Nothing will keep forever not even convenience foods. (Some, like peeled potatoes are even more perishable than unprocessed ingredients.) Rotate stock “ first in first out “. And don’t stock more than necessary.

- Defrost frozen foods properly. Ideally defrost in a tempering box set at 280F to 30oF(-2oC to -1oC) or lacking that, in the refrigerator. This takes advance planning and timing because large items will take several days to thaw.

If you are short of time, the second best way to defrost foods in under cold, running water, in the original wrapper. Never defrost at room temperature or in warm water: the high temperature encourages bacterial growth and spoilage. Do not refreeze thawed foods. Quality will greatly deteriorate. Certain foods like frozen French fries and some individual portion prepared entrée, are designed to be cooked without thawing.

- Know how and to what extend the product has been prepared. Partially cooked foods need less heating in final preparation than do raw foods. Some cooks prepare frozen, cooked crab legs, for example as though they were raw; by the time the customer receives them, they are over cooked, dry and tasteless. Frozen vegetables, for a second example, have been blanched and often need only to be heated briefly. Manufactures are happy to give full directions and servings suggestions for their products. At least you should read the package directions.

- Use proper cooking methods. Be flexible. Much modern equipment has been designed especially foe convenience foods. Don’t restrict yourself to conventional ranges and ovens if compartment steamers, convention ovens, or microwave ovens might do better job more efficiently.

- Treat convenience food as though you, not the manufacturer, did the pre preparation. Make the most of your opportunity to use creativity and to serve the best quality you can. Your final preparation, plating, and garnishing should be as careful as though you made it from scratch.

PORTION CONTROL

Portion control, mean s measuring portions served to ensure that the amount is correct, and that recipe have proper yield. Portion control is primarily, the matter of measurement and measurement begins at the beginnings of preparations, not at the serving line. Portion control begins when you measured ingredients for a recipe, when you make up hamburgers patties or cut steaks and check them on a portion scale, when you carefully scale a custard mix into individual baking cups or measure the amount of stuffing to go into each stuffed chicken breast. Measurements calls for measuring tools – scales, ladles, scoops and so on. Accuracy is a good kitchen habit to develop. Don’t guess. It can cost you money and customer satisfaction.